Truck Suspension Systems: The Secret to a Smooth & Durable Ride

Have you ever wondered what allows a heavy truck to glide smoothly down the road, conquering even the roughest terrains? The answer lies in its suspension system, a complex yet crucial component that ensures a smooth, safe, and durable ride. Let’s delve into the secrets of truck suspension systems and understand their vital role in efficient truck operation.

The Significance of Truck Suspension Systems: Enhancing Smoothness, Durability & Safety

The truck suspension system, also known as the shock absorber system, is a critical part of a truck’s structure. It acts as a “buffer” between the chassis and the wheels, absorbing impacts from the road surface, reducing vibrations and noise, and protecting passengers and cargo from harsh jolts. Furthermore, the suspension system ensures consistent contact between the tires and the road, contributing to stable and safe handling across various terrains.

Unveiling the Secrets of Truck Suspension Systems: Components & Operation

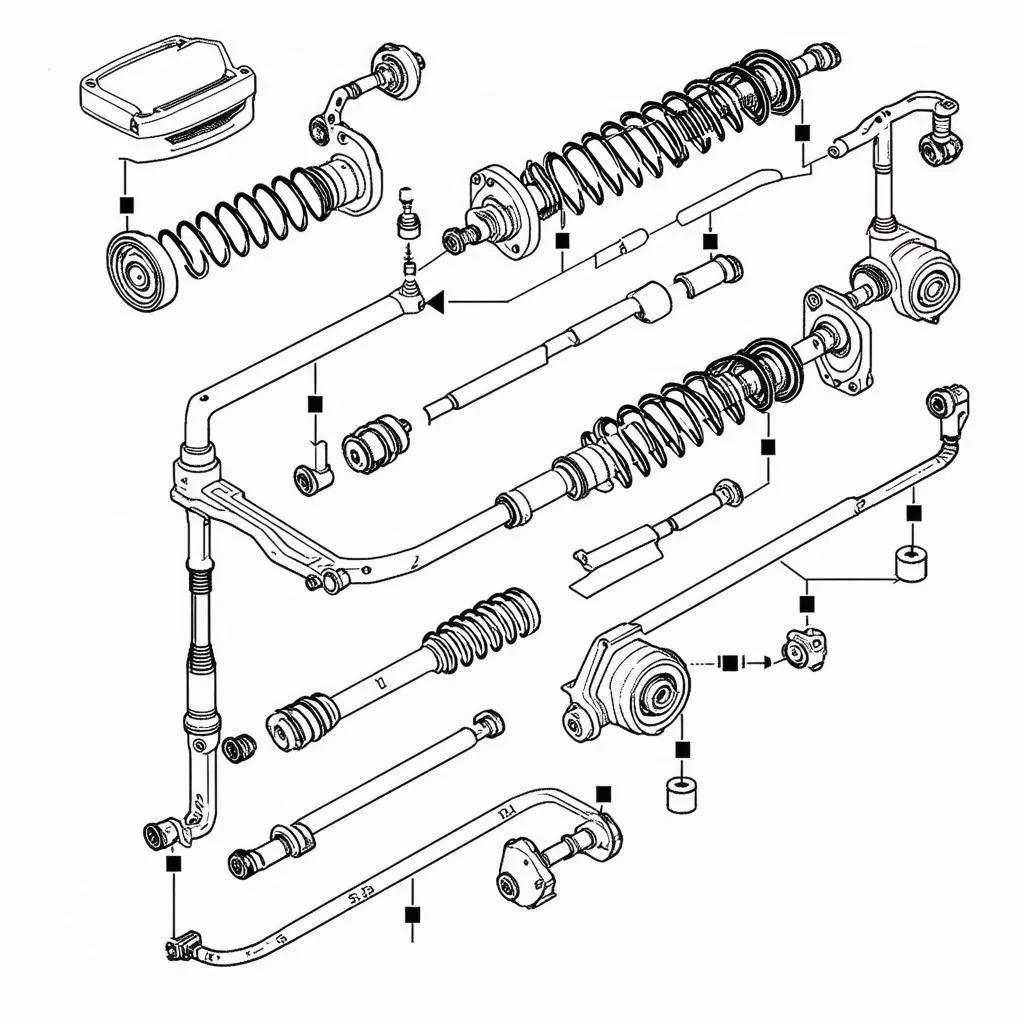

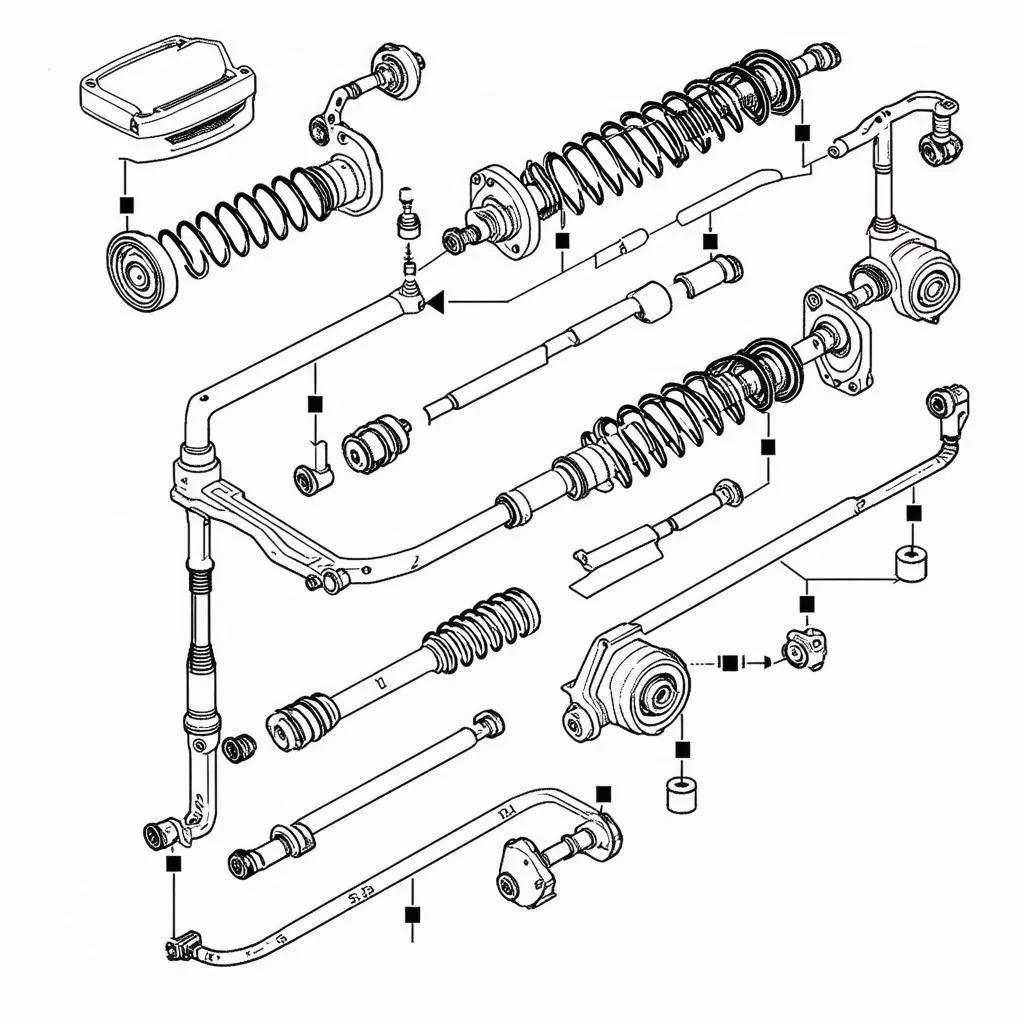

A truck’s suspension system comprises numerous components intricately connected to form a complete system. The main components include:

- Springs: These are the primary force-bearing elements, absorbing impacts from uneven roads and maintaining the truck’s balance. Several types of springs are used in trucks, each with its own advantages and disadvantages:

- Leaf Springs: Commonly used in heavy-duty trucks, known for their high durability and load-bearing capacity.

- Coil Springs: Used in lighter trucks, offering compact size and easy installation.

- Helical Springs: Found in high-end trucks, providing excellent shock absorption and a smoother ride.

- Shock Absorbers: These components control spring oscillations, minimizing vibrations and noise. There are two main types:

- Hydraulic Shock Absorbers: Utilize hydraulic fluid for damping.

- Air Shock Absorbers: Utilize compressed air for damping.

- Control Arms: Connect the chassis to the wheel axles, allowing the wheels to move vertically in response to road irregularities.

- Bushings: Facilitate smooth wheel rotation and reduce friction.

- Stabilizer Bars: Help maintain stability during cornering, preventing excessive body roll.

Truck suspension system components

Truck suspension system components

Common Types of Truck Suspension Systems:

Truck suspension systems are categorized into various types based on their intended use and load capacity. Some common types include:

- Dependent Suspension Systems: Simpler and more affordable, often used in light-duty trucks with smaller payloads.

- Independent Suspension Systems: More complex and expensive, providing superior ride comfort and stability, commonly found in heavy-duty trucks with larger payloads.

- Air Suspension Systems: Utilize compressed air to adjust ride height, enabling adaptability to various terrains and load capacities.

- Electronic Suspension Systems: Advanced systems employing sensors and electronic controllers to automatically adjust spring stiffness and damping force, optimizing ride comfort, safety, and fuel efficiency.

Choosing the Right Suspension System for Your Truck: The Key to a Smooth & Durable Ride

Selecting the appropriate suspension system is crucial for ensuring a smooth, safe, and durable truck operation. Consider these factors when making your choice:

- Truck Load Capacity: Heavier loads require stiffer suspension systems.

- Terrain Type: Frequent travel on rough roads necessitates a system with excellent shock absorption.

- Intended Use: Trucks used for cargo transport require durable, high-load-bearing suspension systems.

- Budget: More advanced suspension systems typically come with a higher price tag.

Maintaining Your Truck’s Suspension System: Tips for Preserving Smoothness & Durability

Regular maintenance is essential for optimal performance and longevity of your truck’s suspension system.

- Check Shock Absorber Fluid Levels: Ensure fluid levels are within the recommended range.

- Inspect Spring Tension: Verify that springs are not sagging or broken.

- Inspect Other Components: Regularly check control arms, bushings, stabilizer bars, and other components for wear and tear, addressing any issues promptly.

Truck suspension system maintenance

Truck suspension system maintenance

Frequently Asked Questions About Truck Suspension Systems:

- How does the suspension system affect fuel consumption? A well-maintained suspension system reduces friction and drag, contributing to fuel efficiency.

- How can I tell if my truck’s suspension system has a problem? Common signs include excessive vibrations, unusual noises, body roll during cornering, sagging or uneven ride height.

- When should I replace my truck’s suspension system? Replacement is necessary when components are severely damaged beyond repair or when the system has significantly deteriorated due to age and wear.

- Does the suspension system impact truck safety? The suspension system directly affects safety by ensuring stability and preventing skidding or rollovers.

Conclusion:

The suspension system is a vital component of any truck, ensuring a smooth, safe, and durable ride. Understanding its intricacies allows for efficient operation, fuel savings, and prolonged truck lifespan.

For any questions regarding truck suspension systems, contact XE TẢI HÀ NỘI. We are available 24/7 to assist you.

Leave your comments below and share this article if you found it helpful.

About us

Chúng Tôi luôn muốn trao đến tay khách hàng một sản phẩm tâm đắc nhất, một chiếc XE TẢI tốt nhất mà mọi người luôn muốn sở hữu.