Car Leaf Spring Structure: A Comprehensive Guide

A car leaf spring, also known as a leaf spring, is a crucial part of a vehicle’s suspension system, responsible for shock absorption and maintaining stability during movement. While seemingly simple, the leaf spring structure plays a vital role in ensuring a smooth and safe ride. This article will delve into the detailed structure of a car leaf spring, from its operating principles to the common types available on the market.

The Role of Leaf Springs in the Suspension System

Car leaf springs operate based on the principle of elasticity, absorbing vibrations and shocks from the road surface, contributing to a smoother ride. They also ensure consistent tire contact with the road, maintaining traction and vehicle control. Especially in trucks, leaf springs bear the load of cargo, distributing weight evenly across the vehicle frame. Following this section, we will explore the components that make up this essential part. Learn more about car differentials.

Detailed Analysis of Car Leaf Spring Structure

Car leaf springs are typically composed of multiple layers of high-elasticity steel, stacked on top of each other. The central leaf spring, known as the main leaf, is the longest and is curved. The remaining leaf springs gradually shorten towards both ends and are called auxiliary leaves. All leaf springs are connected by a center bolt and spring clamps. This structure allows the leaf spring to withstand heavy loads and exhibit excellent elastic deformation.

Main Components of a Car Leaf Spring

- Main Leaf: The longest leaf spring, bearing the primary load and determining the spring’s stiffness.

- Auxiliary Leaves: Shorter leaf springs that support the main leaf and increase load capacity.

- Center Bolt: Connects all the leaf springs together.

- Spring Clamps: Secure the leaf springs in place, preventing slippage.

- Rubber Pads: Reduce friction between the leaf springs and minimize noise during vehicle operation.

Detailed diagram of a car leaf spring

Detailed diagram of a car leaf spring

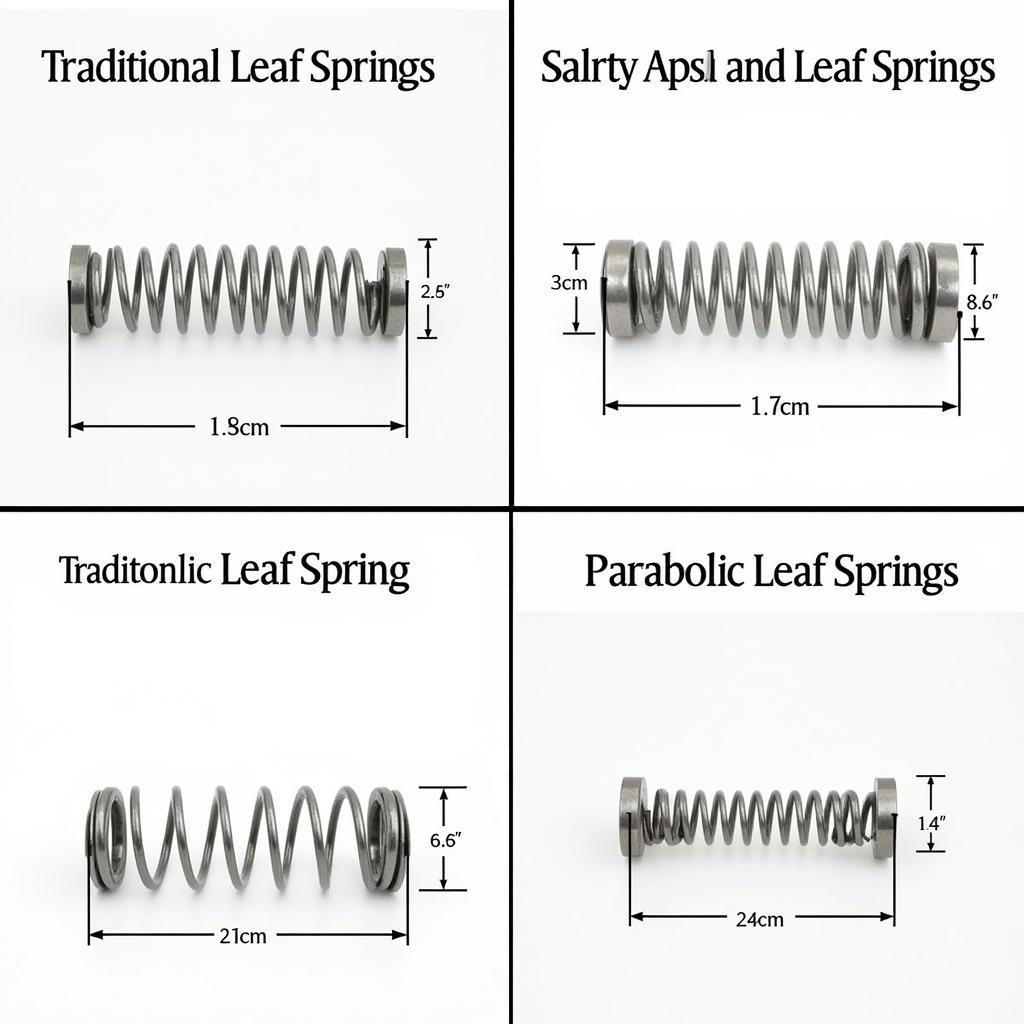

Common Types of Car Leaf Springs

Various types of car leaf springs are available on the market, each with its advantages and disadvantages. Some common types include:

- Leaf Springs: Traditional leaf springs widely used in trucks.

- Parabolic Leaf Springs: Thinner and lighter than traditional leaf springs, providing a smoother ride.

- Air Springs: Utilize compressed air for shock absorption, commonly found in high-end vehicles.

Choosing the Right Car Leaf Spring

Selecting the appropriate car leaf spring depends on several factors such as load capacity, vehicle type, and operating conditions. For heavy-duty trucks, leaf springs with high stiffness are necessary to ensure sufficient load-bearing capacity. For passenger vehicles, softer leaf springs provide a more comfortable ride. Consult with experts to choose the most suitable leaf spring for your vehicle. The structure of a car engine is also an important topic; you can learn more at car engine structure.

Common types of car leaf springs

Common types of car leaf springs

Car Leaf Spring Maintenance and Repair

Car leaf springs are subjected to significant stress and require regular maintenance to ensure optimal performance and longevity. Periodic inspection and lubrication will reduce friction between the leaf springs, preventing squeaking and damage. If signs of damage such as cracks, breaks, or deformation are detected, replace the leaf spring immediately to ensure safe operation. You can also learn more about leaf spring steel.

Signs of Car Leaf Spring Damage

- Vehicle leaning to one side.

- Squeaking noises during movement.

- Poor road grip.

- Excessive vibration when driving over uneven surfaces.

Regular car leaf spring maintenance

Regular car leaf spring maintenance

Conclusion

While seemingly simple in design, the car leaf spring plays a crucial role in ensuring vehicle safety and performance. Understanding the structure and various types of car leaf springs will enable you to make informed choices regarding selection and maintenance, contributing to the longevity of your vehicle.

FAQ

- When should car leaf springs be replaced?

- What is the lifespan of a car leaf spring?

- Which types of car leaf springs are suitable for trucks?

- How much does it cost to replace a car leaf spring?

- How can you tell if a car leaf spring is damaged?

- How to maintain car leaf springs?

- How do car leaf springs affect vehicle performance?

Common Scenarios and Questions

Scenario 1: A truck carrying heavy loads frequently experiences leaf spring sagging. What are the causes and solutions?

Scenario 2: A car makes an unpleasant noise when driving over bumps. Could it be due to damaged leaf springs?

Scenario 3: Which type of leaf spring should be chosen for a 1-ton or 2-ton truck?

Suggested Related Articles and Questions

You can learn more about tire repair in Da Nang and car air conditioning system models.

About us

Chúng Tôi luôn muốn trao đến tay khách hàng một sản phẩm tâm đắc nhất, một chiếc XE TẢI tốt nhất mà mọi người luôn muốn sở hữu.