Understanding Drum Brakes for Safe Truck Operation

“Better safe than sorry” – especially when driving “kings of the road” like trucks. One of the most crucial components requiring attention is the braking system, particularly drum brakes – the “silent heroes” ensuring safety on every journey. Let’s explore the detailed structure of drum brakes with Xe Tai Ha Noi, understanding their operating principles and maintenance methods to guarantee absolute safety for you and the community.

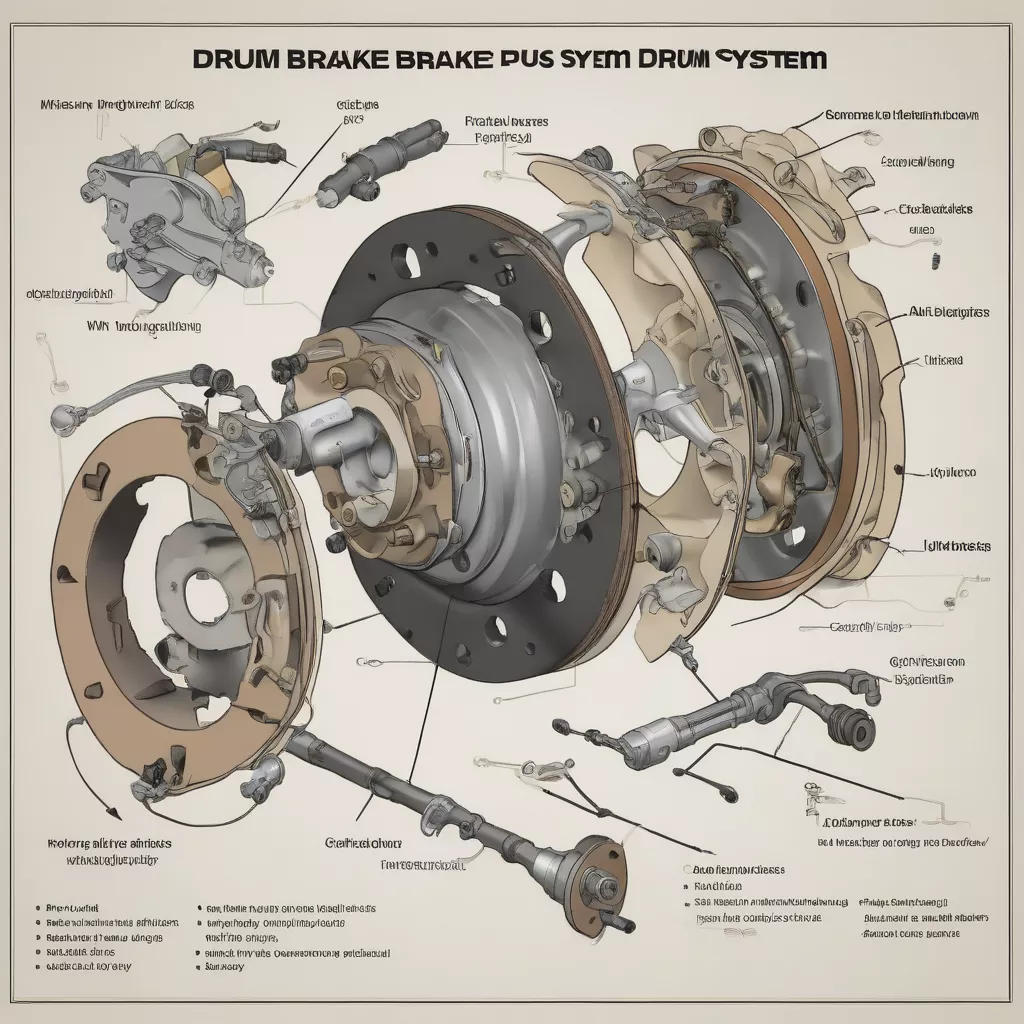

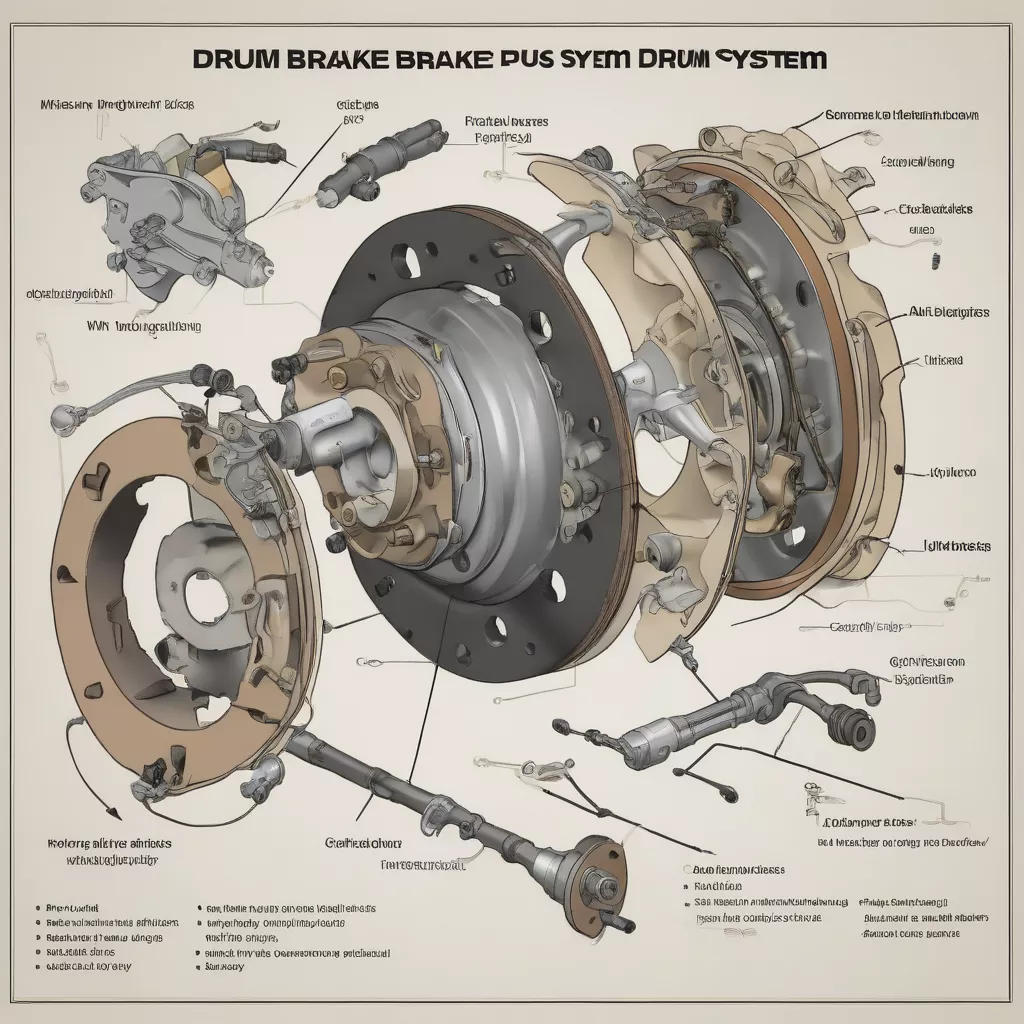

Detailed Analysis of Drum Brake Structure

To understand drum brakes, imagine watching a magic show with a mystical drum. When you apply the brakes, the “magic wand” – the hydraulic piston – acts on the “drum surface” – the brake shoes, creating friction. This friction helps the truck decelerate safely.

1. Main Components:

- Drum: This is the stationary part, shaped like a drum, usually made of cast iron or steel.

- Brake Shoes: Mounted inside the drum, brake shoes are made of high-friction, heat-resistant material. When you brake, the shoes rub against the drum to slow the vehicle.

- Hydraulic Piston: Like a “bridge,” the hydraulic piston transmits force from the brake pedal to the brake shoes, making them contact the drum.

- Return Springs: The “balance keepers,” return springs bring the brake shoes back to their original position after you release the brakes.

- Adjuster Assembly: This component adjusts the distance between the brake shoes and the drum, ensuring optimal braking performance.

2. Operating Principle:

- When you press the brake pedal, brake fluid is pushed to the hydraulic piston.

- The hydraulic piston pushes the brake shoes against the drum, creating friction.

- This friction converts kinetic energy into heat, slowing the truck down.

- When you release the brake pedal, the return springs retract the brake shoes, ending the braking process.

Price List for Drum Brake Inspection and Maintenance Services at Xe Tai Ha Noi:

| Service | Price (VNĐ) |

|---|---|

| Brake System Inspection | 200.000 |

| Drum Brake Cleaning | 300.000 |

| Brake Shoe Replacement | Contact Us |

| Drum Replacement | Contact Us |

Note: Prices may vary depending on the vehicle model and condition.

Important Notes:

- Regularly inspect the braking system, especially before long trips or heavy loads.

- Choose a reputable garage like Xe Tai Ha Noi to ensure quality service and replacement parts.

- Do not ignore unusual signs from the braking system, such as the vehicle pulling to one side when braking or strange noises.

Drum Brake Components

Drum Brake Components

Frequently Asked Questions:

1. What are the advantages of drum brakes compared to disc brakes?

Drum brakes have a simpler design and lower maintenance costs. However, their braking efficiency is not as high as disc brakes, especially in slippery conditions.

2. When should drum brake shoes be replaced?

Generally, brake shoes should be replaced when their thickness is about 3-4mm.

3. How can you tell if a drum is worn out?

A worn drum often exhibits signs like vehicle vibration during braking or loud screeching noises.

How to Purchase at Xe Tai Ha Noi:

For consultation and scheduling drum brake maintenance, please contact Xe Tai Ha Noi at hotline 0987.654.321 or visit us directly at:

- Showroom 1: 123 Giai Phong Street, Hai Ba Trung District, Hanoi

- Showroom 2: 456 Nguyen Trai Street, Thanh Xuan District, Hanoi

Related Products:

Xe Tai Ha Noi offers a wide range of truck repair and maintenance services, including:

- Brake System Repair

- Engine Maintenance

- Transmission Repair

- …

Xe Tai Ha Noi Garage

Xe Tai Ha Noi Garage

Conclusion

Understanding the structure of drum brakes is key to safe and efficient truck operation. Be a smart driver, always prioritizing regular brake maintenance to ensure safety for yourself and the community. Xe Tai Ha Noi is always with you on every road!

About us

Chúng Tôi luôn muốn trao đến tay khách hàng một sản phẩm tâm đắc nhất, một chiếc XE TẢI tốt nhất mà mọi người luôn muốn sở hữu.